We have been performing air leakage testing on homes for almost 30 years. Utilizing a blower door, we can depressurize (or pull a vacuum) on the home to measure the total air leakage. While the blower door is running, our technicians can walk around a home to identify the individual air leakage sites.

Over the years, we have been involved in several commercial projects where we utilize the same equipment to identify air leakage sites in much larger buildings. Recently, though, the Army Corps of Engineers began requiring Air Barrier Testing and Building Envelope Scans of ALL new projects so we have seen a significant increase in demand for this service.

The Army Corps of Engineers spec usually requires that the inspection follow either ASTM E1827 or ASTM E779 for air leakage testing. Larger buildings obviously require more fan capacity so a 3-fan blower door system may need to be used.

In some cases, multiple 3-fan systems may be needed. The ACOE requirement usually sets the maximum allowable air leakage rate at 0.25cfm@75pa per sf of conditioned building envelope area so by calculating the envelope area, we can determine how many fans will be needed.

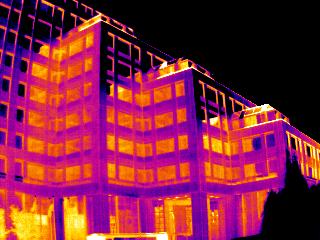

The ACOE spec sometimes requires a Building Envelope Scan, following ASTM C1060 for infrared testing.

During an infrared scan, insulation, moisture, and air leakage problems can be identified. It’s important to have a knowledgeable, certified infrared thermographer perform the inspection…..someone who can interpret the images properly.

We can perform air barrier testing and air leakage testing (following ASTM E1827 and ASTM E779) and a Building Envelope Scan (following ASTM 1060) for you if you ever run into these requirements.